An Ecosystem of Quality

August 21, 2025

The Electrical Wiring Processing Technology Expo, held last May, showed how fast the Wire Harness industry is changing and growing. The Baird Center in Milwaukee was full of industry veterans, ready to connect, learn, and talk about new trends and technologies. One highlight was Mike Nagle’s talk, where he shared insights on the changes in quality systems over time.

Wire Harness Quality: The Start

“When I first got into the industry, the production staff were building wire harnesses by hand and quality management meant manual inspection of each cable and crimp. The main problem at this time was that all the failures in the cable were found after the cables had been added to the car and a failure meant shutting down the assembly line and removing car parts like seats, and dashes so that you could get to the wire harnesses,” Nagle explained. “They were very costly and labor-intensive to remove and repair. Because of this, the car manufacturers wanted everything tested before assembly into the car.”

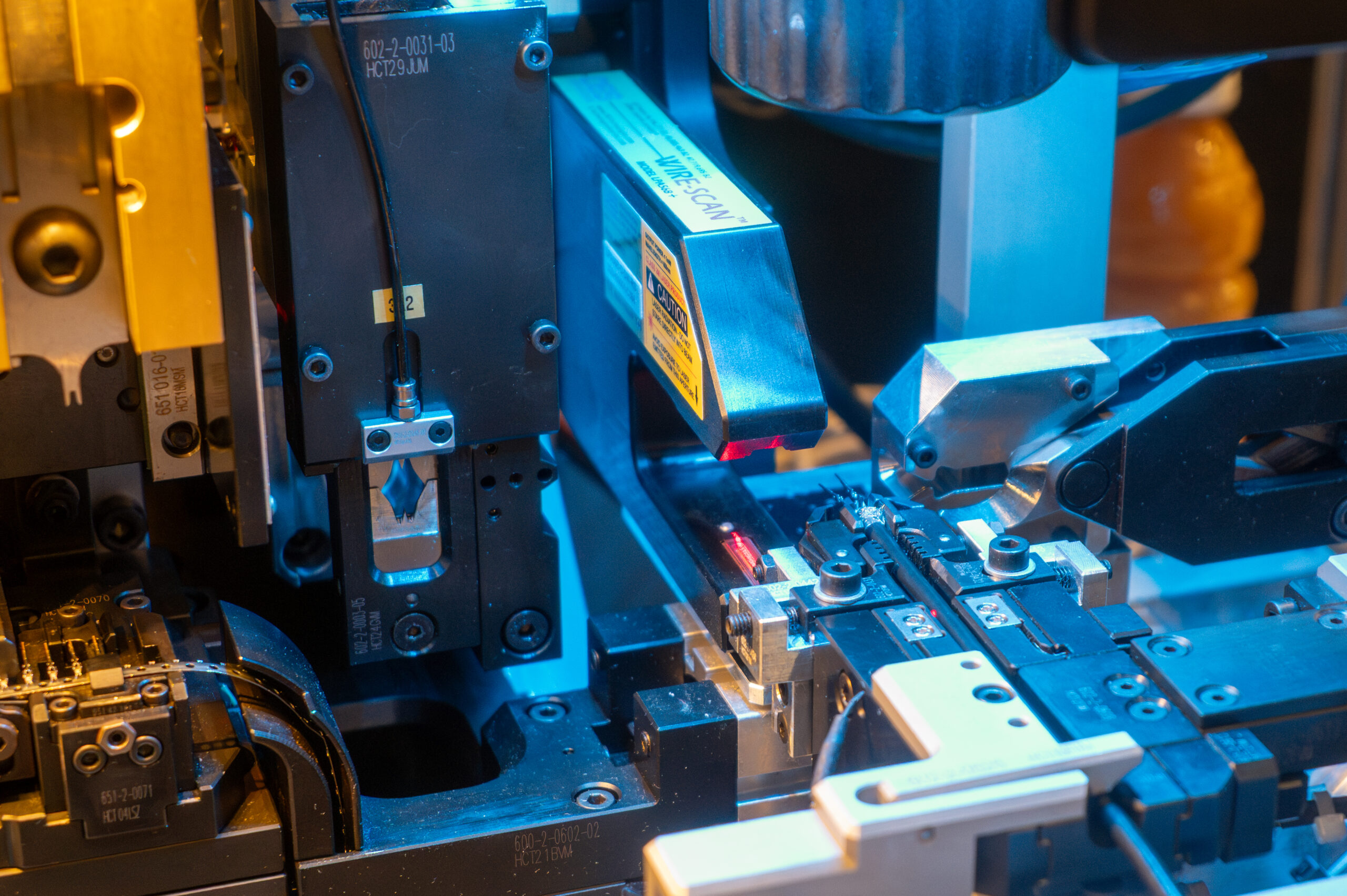

To improve product quality, faults began to be found earlier in the building process—sometimes at the very start, when parts only cost pennies. As the Wire Harness Industry grew, spreading to Mexico, North Africa, and Asia, quality control devices became essential. The industry worked hard to bring together different devices into one system to produce better products, reduce waste, and boost both revenue and customer satisfaction.

Trends in the Wire Harness Industry

This led to four big trends:

- Automation in wire harness assembly

- Global standards for product quality

- Making wires thinner to handle higher copper prices and reduce copper in vehicles

- Making some wires thicker to lower resistance and vehicle weight, which helps electric car batteries last longer

“The quality management systems allowed us to verify every part needed to make the wire harness before the parts were produced,” said Nagle. “This allowed for traceability – the ability to track materials, parts and finished products through all stages of production – and prevented incorrectly manufactured parts from making it to the next step in the process.”

The Future of Quality Management

Looking ahead, quality management is set to get even better as new technologies like AI become more common. These tools make processes faster and more accurate. Nagle said AI directly improves press machines and makes quality systems more valuable. Now, the industry aims for full traceability in every batch that gets made.

“In the past, this traceability was limited to pass/fail, and in some cases simple data such as peak force. However, the market is demanding more,” Nagle asserted. “Now, more than ever, crimp monitors and vision systems are playing a much larger role in real-time quality management, specifically in the amount and quality of data available for traceability.”